If you've ever drooled over a lightweight race car or lusted after a high-end bike, odds are you've seen carbon fiber. Feather-light with a look straight out of a sci-fi flick, it’s now everywhere from car hoods and spoilers to street bike frames and even airplane wings. But there’s a weird whispered fear floating around any garage or bike shop: does carbon fiber crack as it ages? Is it really as bombproof as it looks, or is the whole thing living on borrowed time? You know what? Not all carbon fiber is the same, and the real answer can surprise you.

What Makes Carbon Fiber Different from Other Materials?

Let’s start with why anyone uses carbon fiber in the first place. Steel and aluminum feel tough, but carbon fiber brings a different kind of magic—it’s five times stronger than steel, at one-fifth of the weight. No wonder it shows up in Formula 1 cars, supercars, mountain bikes, and aerospace stuff. But here’s the twist: carbon fiber isn’t a single material. It’s made up of super-thin strands, woven like fabric, then set in resin. Picture high-tech cloth frozen into whatever shape you want. That’s where the power—and the problem—comes in.

See, carbon strands are crazy strong if you pull along their length, but they aren’t invincible in every direction. Most failures in carbon parts aren’t the fiber breaking—they’re cracks or splits starting in the resin that binds those fibers together. Think of the resin as the glue that holds the puzzle together. Too much stress, and the glue can let go.

Here’s something cool: perfectly made carbon fiber doesn’t rust or corrode the way metals do. It laughs at most chemicals, resists weather, and shrugs off water. That’s why you’ll see it on hypercars that sit in the rain and on boats that spend years in salt water. However, what carbon fiber hates is getting crushed, banged, or twisted—especially in ways the designer didn’t expect. When hit with a sharp, pointed force, carbon can crack suddenly and sometimes without warning.

The exact lifetime of a carbon component depends a ton on the resin, the quality of manufacture, and how the part is used. NASA trusts it for rockets; pro cyclists trust it for brutal races. But not all carbon is made equal. Items built with cheaper resins, sloppy layer placement, or rushed quality control are more likely to let you down over time. High-end bike frames, for example, are hand-laid and stress-tested. Knockoff aftermarket car hoods? Maybe not so much.

Check this table for a quick look at how carbon fiber compares with some classic materials in longevity tests:

| Material | Approximate Service Life (years) | Common Failure Mode |

|---|---|---|

| Steel (mild, untreated) | 15-50 | Rust/corrosion, fatigue |

| Aluminum Alloy | 10-35 | Fatigue cracks, corrosion |

| Carbon Fiber | 10-30+ | Delamination, cracking after impact |

Note: "Service life" is a ballpark—it wildly depends on the part and how it’s treated.

What Causes Carbon Fiber to Crack Over Time?

You see fancy carbon body panels on the gram, but have you ever seen what they look like after a bad crash? Here’s the dirty secret: while carbon fiber can last decades if treated right, it can fail surprisingly fast if things go wrong. Let’s break down why.

First, the big threat is impact damage. Imagine dropping a carbon fiber bike frame on a jagged rock or getting rear-ended while running a carbon lip spoiler. The outer shell might flex, and sure, it may look okay, but there’s often a network of tiny cracks in the resin underneath—some not even visible to the naked eye. This cracks the surface and, if left ignored, can grow with every bump or flex, slowly turning a "hairline" problem into a full-on break.

Here’s the catch: unlike metals, which usually bend before they break (giving you a fighting chance to notice), carbon fiber can store up damage and then fail suddenly, often without much warning. It’s why race teams scan critical carbon with ultrasound after crashes. Most of us don’t have that luxury on the street, so the risk is real.

Environmental stress is another sneaky issue. Cheap resins can get brittle in extreme cold or soften when summer heat cranks through the roof (black carbon hood in the sun, anyone?). UV rays alone won’t harm the fibers, but they can slowly break down the resin "glue" if the part isn’t coated properly. That’s why most visible carbon parts have a UV-stable clear coat—skip that, and your expensive carbon part might start breaking down sooner than you’d expect.

Fatigue is the third enemy. Carbon fiber loves consistent loads, but repetitive flexing can break down even the best composite over time. For example, a set of carbon road bike wheels clocking thousands of rough miles might eventually develop fine cracks where the material flexes most. Car suspension parts or body panels exposed to constant vibration face the same risk—the more extreme the flexing or loads (real-world potholes, repeated bumps), the greater the chance for microcracks to start.

Here’s what’s wild: sometimes, cracks in carbon fiber don’t grow for years, and sometimes, a single hard knock can ruin a part outright. It all comes down to how the energy hits the fibers and resin. Unlike old-school steel, there’s no easy way to hammer carbon "back into shape." Once it cracks, repair can be tricky and matters a lot what exactly broke and how deep the damage runs.

How to Spot Cracks and Damage in Carbon Fiber Parts

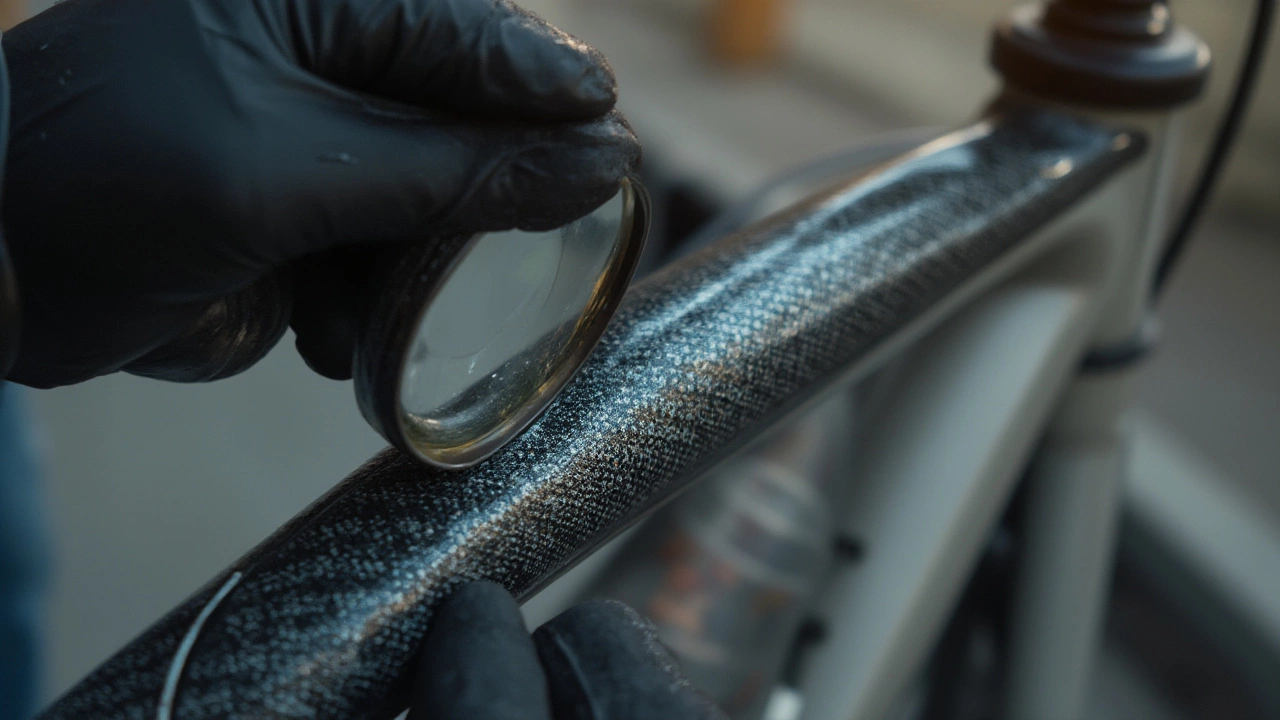

Spotting trouble early is a life saver (sometimes literally—just ask anyone who rides carbon bikes at high speeds). Don’t buy into the myth that carbon fiber always falls apart out of sight. There are real clues—if you know where to look and what to feel for. It just takes a little detective work.

The most obvious sign is a visible crack or chip, usually starting at a sharp edge, bolt hole, or spot where the part took a hit. Run a fingertip over suspicious areas—any roughness, raised edges, or places where the smoothness is gone could signal trouble. Also, watch for wrinkling or "spiderwebbing" under the clear coat. Sometimes a damaged part will creak, pop, or sound different when tapped. Small cracks can hide under paint or decals, so always check thoroughly, especially after an impact or accident.

Use a flashlight at shallow angles to highlight surface lines, or lightly tap the part with a small coin. A healthy carbon part usually makes a high-pitched, crisp "tick"; a damaged section can sound dull or muted. It’s a low-budget trick, but surprisingly revealing.

For bigger stuff—say, a hood, side skirt, or trunk lid—check mounting points closely. These areas handle the most stress. Loose bolts, rattling, and uneven panel gaps can signal the resin has broken inside, even if everything looks okay from the outside. Don’t ignore flexing or areas that suddenly feel "loose" or wobbly. Those are red flags.

Here’s a pro-level tip: if you’re buying used carbon gear, always ask about the part’s history. Any serious impact, no matter how small, could mean hidden problems that show up months or years later. Real talk—some sellers won’t even know, and others just won’t say.

If things look suspect or you’re riding/driving at high speeds, consider a non-destructive test like dye penetrant or even a pro ultrasound scan. Yes, it costs cash, but on critical parts—suspension arms, bike forks, major structural panels—it’s worth a lot more than the price of a trip to the ER or a ruined ride.

If you spot damage, it’s best NOT to take risks. Small surface cracks on non-structural parts (like a trim cover) are mostly a cosmetic issue, but on anything critical—especially where loads happen—get a professional check or consider replacing the part altogether.

How to Prevent Carbon Fiber Cracking and Boost Longevity

The best medicine for cracked carbon fiber is prevention, plain and simple. Sure, this futuristic material is durable and tough when handled smartly, but it’s no fan of abuse. If you want your carbon gear to outlast trends, here’s what you actually need to do:

- Always install with proper torque and hardware. Using the wrong bolts, over-tightening, or mismatched metal hardware can pinch or crush the fibers, starting microcracks at mounting spots. Stick to factory torque specs and use load-spreading washers when needed.

- Watch for impacts, even minor ones. Parking-lot fender bender? Dropped your pricey carbon fiber helmet? That hidden damage is real. Even if the part "looks fine," a pro check is better than blind trust.

- Keep UV-protective coatings up to date. If the clear coat gets scratched or dull, buff it out or reapply. Stopping UV rays from reaching the resin keeps things strong longer.

- Clean with mild soaps and gentle cloths. Harsh chemicals aren’t usually a problem, but scrubbing too hard or using abrasives can start surface scratches—places where future cracks can start.

- Store carbon fiber away from extreme heat. While the fibers won’t melt, cheap resins definitely soften under direct sun (think boiling-hot hood in July), making them weaker over time.

- Don’t ignore odd sounds. Creaks, pops, or "soft" spots that you notice after an impact almost always mean it’s time to investigate.

- For parts that flex constantly (like bike wheels or car suspension arms), check for signs of fatigue every few months with a careful eye and a good light.

- Use real, high-quality carbon. There are scary fakes and "carbon-look" plastics out there. Real carbon fiber should have woven layers, consistent finishes, and, usually, a much higher cost. Don’t trust bargain-bin parts with your safety or vehicle.

One last word—don’t let the risk of cracking scare you off carbon fiber. The same reason it’s used for F1 cars and business jets (ultra-high strength and featherweight) is why it continues to take over in automotive performance, bikes, and even daily driving. But like anything high-tech, it demands respect. It wants to be installed right, used smart, and checked occasionally. Treat it right, and your carbon fiber will stay strong way longer than most people expect.