Wheel Spacer Safety Calculator

Calculate Your Spacer Safety

Enter your spacer details to see if they're safe for your wheel bearings

Safety Assessment

Your spacer setup appears safe for your vehicle. The additional load on your wheel bearings is minimal when properly installed.

Recommended: Keep within 15mm per side for street cars. Check bearings every 10,000 km.

Safety Assessment

Your spacer setup is moderately risky. The additional leverage could accelerate wheel bearing wear over time.

Recommendation: Stay under 15mm per side. Consider upgrading to hub-centric spacers for safer operation.

Safety Assessment

Your spacer setup is high risk. The additional leverage significantly increases stress on wheel bearings.

Urgent Recommendation: Reduce spacer thickness below 15mm or replace with hub-centric spacers. Check bearings immediately.

Warning: Using bolt-centric spacers over 15mm creates significant leverage that can lead to premature wheel bearing failure within 20,000-30,000 km.

Ever seen a car with wheels pushed out to the fenders and wondered if those spacers are quietly killing the wheel bearings? You’re not alone. Thousands of car enthusiasts slap on spacers for that aggressive stance, but rumors swirl that they’re a silent killer for bearings. The truth? It’s not that simple. Spacers themselves don’t automatically destroy wheel bearings - but wrong spacers or bad installation absolutely can.

How Wheel Bearings Actually Work

Wheel bearings sit inside the hub assembly and let the wheel spin smoothly with minimal friction. They handle two main forces: radial load (the weight of the car pressing down) and lateral load (side forces from cornering, braking, or uneven roads). When everything’s aligned right, the bearing spins cleanly, lasting 100,000 miles or more.

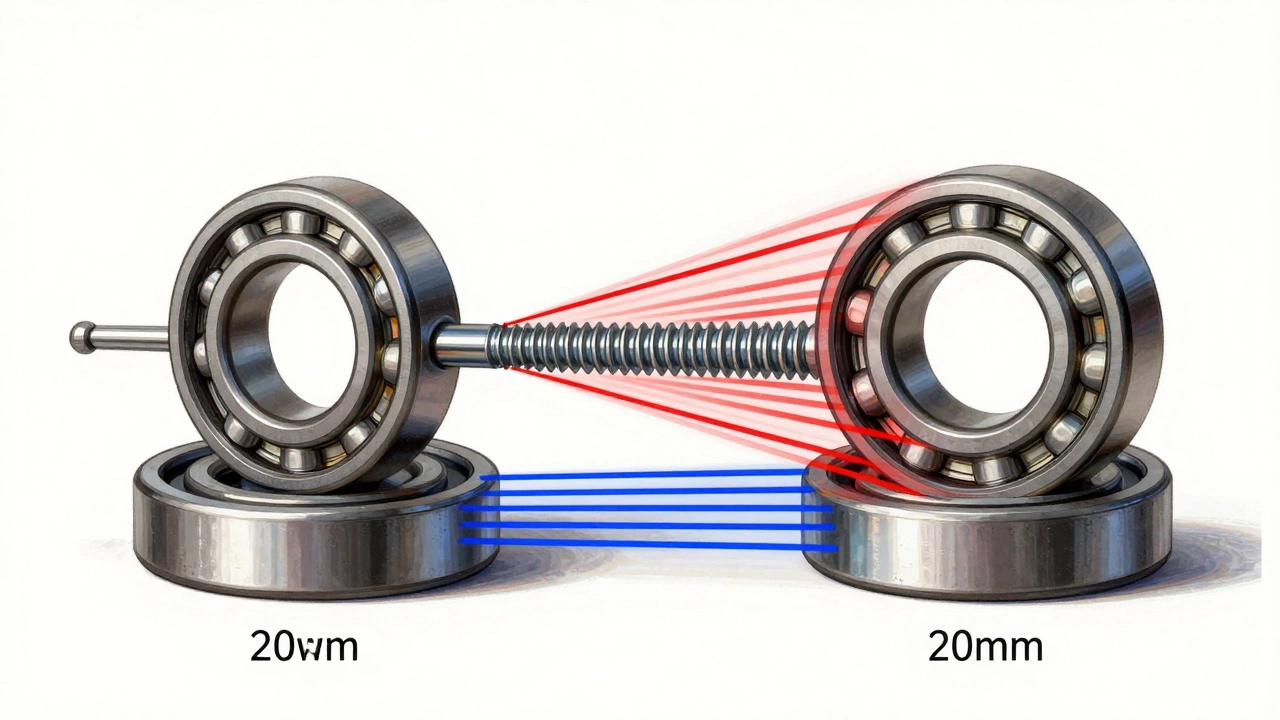

But when you add spacers, you’re changing the distance between the hub and the wheel. That changes how the bearing is loaded. Think of it like holding a heavy barbell close to your body versus holding it out with your arms fully extended. The farther out the weight is, the more stress you feel on your shoulder joint. Same idea with wheel bearings.

What Happens When You Add Spacers

Adding spacers increases the distance between the wheel’s mounting surface and the hub. That creates more leverage on the bearing. The longer the lever arm, the more force the bearing has to absorb every time you hit a bump, turn a corner, or brake hard.

For example, a 15mm spacer on a 2,000 kg car doesn’t just add 15mm - it multiplies the lateral force on the bearing by about 15%. That might sound small, but over thousands of miles, that extra stress adds up. Bearings aren’t designed to handle that kind of sustained overload. The result? Premature wear, play in the wheel, grinding noises, and eventually, bearing failure.

Not All Spacers Are Created Equal

The real danger isn’t the spacer itself - it’s the type you use and how it’s installed.

HUB-CENTRIC SPACERS fit snugly over the hub flange, so the hub still carries the load. The wheel bolts just hold the wheel in place. This is the safe way. The bearing load stays close to its original design path.

BOLT-CENTRIC SPACERS - the cheap kind - rely entirely on the wheel studs to center the wheel. That means the studs take on extra bending stress, and the bearing gets pushed sideways. These are the ones that cause problems. You’ll often see these on eBay or Amazon for under $50 a set. They’re a gamble.

Quality hub-centric spacers are machined from 6061-T6 aluminum or steel, with precise tolerances. They come with longer, high-strength wheel studs or bolts that are torque-rated for the job. Cheap spacers? Often cast aluminum, uneven thickness, no hub bore matching your car’s hub. They wobble. And wobbling kills bearings.

How Much Spacer Is Too Much?

There’s no universal number, but here’s what mechanics and engineers agree on: stay under 15mm per side for most street cars. Beyond that, you start entering high-risk territory.

Why 15mm? Because most factory suspension components - control arms, ball joints, tie rods - are designed to handle slight changes in geometry within that range. Beyond 15mm, you start altering caster, camber, and scrub radius in ways that increase tire wear, reduce steering feel, and overload the bearings.

Track cars or heavily modified vehicles sometimes use 20-25mm spacers - but they’re paired with upgraded suspension parts, stronger bearings, and regular inspections. This isn’t for daily drivers.

Signs Your Wheel Bearings Are Suffering

If you’ve installed spacers and hear a new humming or grinding noise from the wheels - especially when turning - pay attention. Other signs:

- Steering wheel vibration at highway speeds

- Play in the wheel when you lift the car and shake the tire side-to-side

- Uneven tire wear, especially on the outer edges

- ABS or traction control lights coming on randomly

These aren’t normal. If you notice any of these after installing spacers, get the bearings checked immediately. Waiting until the wheel falls off isn’t a plan.

Installation Mistakes That Kill Bearings

Even the best spacers can fail if installed wrong. Here are the top three mistakes:

- Not torquing bolts properly - Under-torqued bolts allow movement. Over-torqued bolts stretch the studs and distort the hub. Always use a torque wrench. For most cars, it’s 85-100 Nm. Check your manual.

- Using old or worn studs - If your wheel studs are stretched, corroded, or damaged, spacers make things worse. Replace them with high-strength aftermarket studs designed for spacers.

- Skipping hub cleaning - Rust, dirt, or paint on the hub surface prevents the spacer from seating flat. That creates a wobble. Always clean the hub with sandpaper or a wire brush before installing.

When Spacers Are Actually Safe

Spacers aren’t evil. Used correctly, they’re a legitimate modification.

Many OEMs use spacers in factory setups - think Subaru WRX STI with its wide track, or BMW M3s with factory rear spacers. These are engineered systems with bearings rated for the extra load.

Safe spacer use means:

- Using hub-centric spacers (not bolt-centric)

- Staying under 15mm per side

- Installing with torque wrench and new hardware

- Checking bearing play and noise every 10,000 km

- Replacing bearings proactively if you drive aggressively or on rough roads

Some people run 20mm spacers without issues - but they’re driving gently, on smooth roads, with upgraded suspension and bearings. That’s not the norm. Don’t assume you’re the exception.

Alternatives to Spacers

If you want wider stance without risking bearings, consider:

- Wider wheels with lower offset - This moves the wheel out without adding leverage on the bearing. Best long-term solution.

- Aftermarket control arms - Allow you to run wider wheels with proper geometry, no spacers needed.

- Custom hub adapters - Machined to match your hub and wheel, with integrated bearings. Expensive, but safe.

These options cost more upfront, but they preserve your suspension health and last longer. Spacers are a shortcut. Shortcuts often lead to breakdowns.

Final Verdict: Are Spacers Bad for Wheel Bearings?

Spacers aren’t inherently bad - but they’re high-risk if misused. Cheap, bolt-centric spacers over 15mm? Yes, they’ll kill your bearings faster than you think. High-quality, hub-centric spacers under 15mm, installed correctly? They’re fine for most street cars.

Think of it like tires: you can drive on cheap, worn tires for a while - but you’re asking for trouble. Same with spacers. If you want the look, do it right. Invest in quality hardware, install it properly, and check your bearings regularly. Your wallet - and your safety - will thank you.

Can I use 20mm spacers without damaging my wheel bearings?

It’s possible, but not recommended for daily driving. 20mm spacers significantly increase leverage on the bearing, especially if they’re not hub-centric or if your suspension isn’t upgraded. You’ll likely see premature wear within 20,000-30,000 km. Track cars with reinforced components can handle it, but street cars should stick to 15mm or less.

Do I need longer wheel studs when using spacers?

Yes - always. Spacers add thickness between the hub and wheel, so your stock studs may not engage enough threads in the wheel. You need longer, high-strength studs (usually grade 12.9) that allow at least 6-8 full threads of engagement. Never use stock studs with spacers over 5mm.

Are hub-centric spacers worth the extra cost?

Absolutely. Hub-centric spacers transfer load through the hub, not the studs. This reduces stress on both the wheel studs and the bearing. Cheap bolt-centric spacers can cost $30, but they’re a false economy - they cause vibrations, uneven wear, and bearing failure. Good hub-centric spacers cost $150-$250, but they’re the only safe choice.

How often should I check my wheel bearings after installing spacers?

Check them every 10,000 km if you’re using spacers, especially if you drive on rough roads or corner hard. Look for play by shaking the tire while it’s lifted, listen for new noises, and have a mechanic inspect them during oil changes. Don’t wait for symptoms - prevention is cheaper than replacement.

Can spacers cause uneven tire wear?

Yes. Spacers change the wheel’s position relative to the suspension geometry, which can alter camber and toe angles. This leads to faster wear on the inner or outer edges of the tire. If you notice uneven wear after installing spacers, get a wheel alignment - and consider whether the spacer size is too aggressive for your setup.