If you’ve spotted a line or spider‑web on your carbon‑fiber hood, spoiler or splitter, you’re probably looking at a crack. Carbon fiber is strong, but it’s not indestructible. A crack can spread quickly if you ignore it, leading to costly replacements. This guide shows you why cracks happen, what you can do right now, and how to keep your carbon parts looking pristine.

Most cracks start with impact – a stone, curb hit, or even a small debris slam can create a hidden flaw. Temperature swings also play a role; when the resin expands in heat and contracts in cold, stress builds up at weak spots. Poor installation or mismatched adhesives can add extra strain, especially on parts that flex a lot, like a rear diffuser.

Another sneaky cause is overspray from paint or chemicals. Some solvents can soften the resin, making it easier for a tiny chip to turn into a visible crack. Finally, DIY modifications that involve drilling or cutting without proper reinforcement are a fast track to failure.

First thing – stop using the part until you’ve assessed the damage. Small hairline cracks can be fixed with a carbon‑fiber repair kit. Clean the area with isopropyl alcohol, sand lightly with 320‑grit paper, then apply the resin‑filled epoxy patch. Press it in, let it cure, and sand smooth before polishing.

For bigger cracks, you’ll need a professional. They’ll sand out the damaged zone, lay new woven carbon cloth, and infuse it with high‑strength epoxy. This method restores the original strength and keeps the weight low.

Prevention is cheaper than repair. Keep carbon parts clear of rocks, use a soft brush and mild soap for cleaning, and avoid high‑pressure washers that can force water into tiny gaps. If you add accessories, use bonding agents recommended by the manufacturer and let them cure fully before driving.

Also, watch your car’s temperature. When parking under a hot sun, use a shade or car cover to reduce thermal stress. In cold climates, avoid sudden blasts of hot water on carbon surfaces – the rapid expansion can create micro‑cracks that grow later.

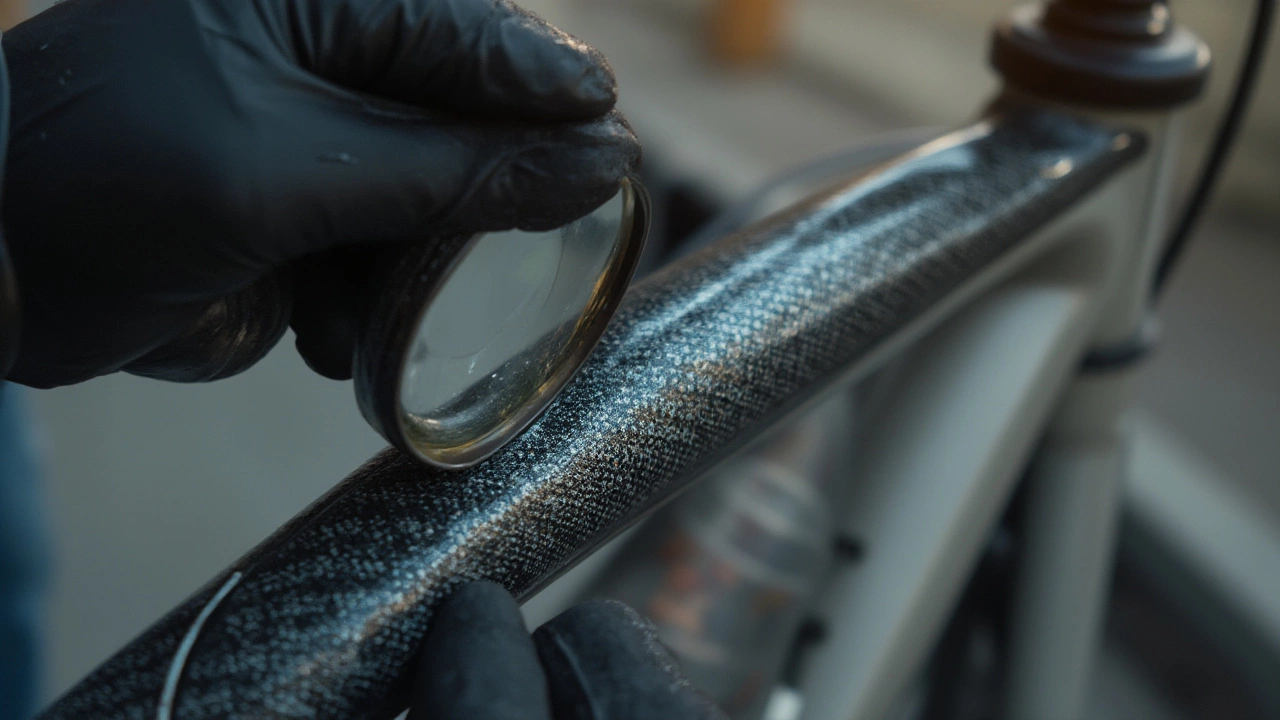

Finally, regular inspections save money. Check your carbon parts every few months, especially after a road trip on rough terrain. A quick visual scan and a light tap with a plastic tool can reveal hidden splits before they spread.

By spotting cracks early, using the right repair kit, and keeping your carbon components clean and protected, you’ll enjoy the lightweight strength of carbon fiber for years without paying for a full replacement.

Carbon fiber spoilers look great but have hidden weaknesses: brittle resin, UV damage, thermal stress, and poor installation can cause cracks and failure. Know the risks before you buy.

Wondering if carbon fiber cracks over time? Dive into real-world facts, how to spot problems, avoid damage, and make your carbon parts last.