Carbon fiber looks sleek, feels light, and promises high performance. But many owners wonder if it can stand up to daily driving, weather, and the occasional bump. Below we break down the stuff that really matters for keeping carbon fiber parts strong, and give you a few no‑nonsense tips you can start using today.

First, understand that carbon fiber isn’t a single material. It’s a weave of carbon strands held together with a resin matrix. The resin is the weak link – UV rays, high heat, and harsh chemicals can break it down over time. If you live in a sunny climate, the sun can slowly soften the resin, leading to tiny cracks that spread.

Impact is another big factor. A light tap might not show any damage, but repeated stone chips or curb knocks can delaminate layers. That’s why carbon‑fiber body kits on cars often need extra reinforcement at high‑stress points.

Moisture itself doesn’t rust carbon fiber, but water that gets trapped in micro‑cracks can cause the resin to swell. Over time, this can expand the cracks and make the part feel soft.

Finally, the type of coating matters. Some manufacturers finish carbon fiber with clear coats, others use matte paints. A good clear coat adds a UV barrier, while a matte finish might be more porous and need more frequent care.

1. Wash with mild soap. Use a gentle car‑wash soap and a soft microfiber cloth. Avoid aggressive detergents, automatic brushes, or high‑pressure jets that can force water into tiny cracks.

2. Dry quickly. After washing, pat the surface dry. Letting water sit encourages resin swelling and can leave water marks on glossy finishes.

3. Apply a UV‑protective coating. A spray‑on ceramic or polymer coat forms a hard layer that blocks UV and adds water resistance. Reapply according to the product’s schedule – usually every 6‑12 months.

4. Stay clear of harsh chemicals. Acidic cleaners, paint thinners, and brake dust sprayers can eat the resin. If you need to remove stubborn grime, use a carbon‑fiber‑safe cleaner recommended by the part maker.

5. Mind the edges. The edges of carbon‑fiber panels are where cracks start. Use edge protectors or tape when installing or moving parts to avoid chipping.

6. Store indoors when possible. If you have removable carbon‑fiber accessories – splitters, mirrors, or winglets – keep them in a dry, shaded space. This cuts down on UV exposure and accidental impacts.

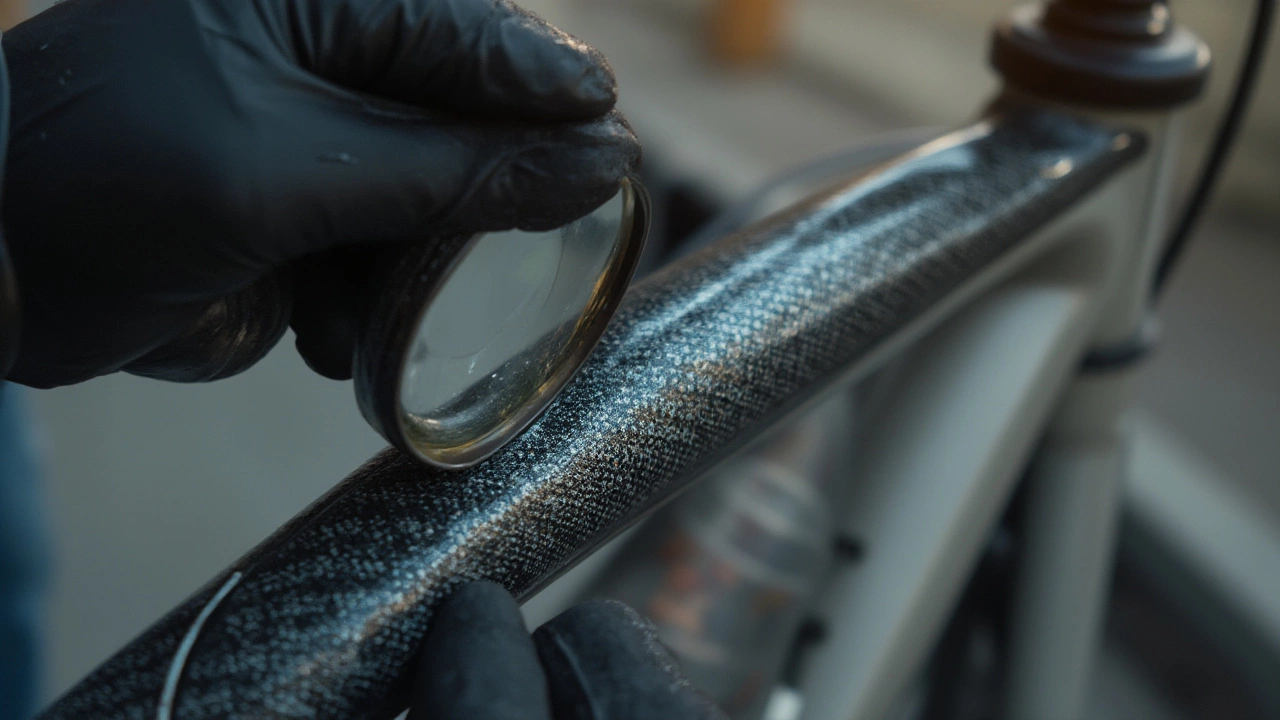

7. Inspect regularly. A quick visual check every few months helps you spot hairline cracks early. Small cracks can often be sealed with a resin‑filled patch kit before they spread.

Putting these habits into practice keeps carbon‑fiber parts looking fresh and performing as intended. You’ll notice less fading, no unexpected softness, and a longer life for expensive upgrades like carbon‑fiber body kits or interior trim.

Remember, carbon fiber’s strength comes from its structure, not from being “indestructible.” Treat it like any high‑performance component: protect it from the sun, avoid rough handling, and give it a proper cleaning routine. Your car will thank you with a sleek look and the confidence that comes from well‑maintained, durable carbon‑fiber parts.

Carbon fiber spoilers look impressive but often cost more, break easily, and offer no real performance benefit for daily drivers. Here’s why they’re a bad investment for most cars.

Carbon fiber spoilers look great but have hidden weaknesses: brittle resin, UV damage, thermal stress, and poor installation can cause cracks and failure. Know the risks before you buy.

Wondering if carbon fiber cracks over time? Dive into real-world facts, how to spot problems, avoid damage, and make your carbon parts last.