When you’re hunting for new rims, the debate usually boils down to two phrases you keep hearing at shops and forums: Aluminum wheels are a type of wheel made entirely from pure aluminum, prized for their lightness and classic look versus Alloy wheels are a blend of aluminum and other metals like magnesium or zinc, engineered to give you strength without the heavy penalty. Both sound appealing, but which one truly delivers on performance, cost, and long‑term reliability? Let’s break it down so you can decide without guessing.

Key Takeaways

- Alloy wheels usually win on strength‑to‑weight ratio, making them a better choice for sportier driving.

- Pure aluminum wheels are lighter but can be softer and more prone to cracking under heavy loads.

- Cost differences shrink as manufacturing tech improves; today’s alloys often cost only a bit more than pure aluminum.

- Corrosion resistance and brake‑cooling performance depend more on coating and design than on the base metal.

- For everyday commuting, either option works, but if you value track days or aggressive cornering, alloy wheels have the edge.

How Wheel Materials Affect Weight

Weight is the first thing most drivers notice. A lighter wheel reduces unsprung mass, which improves handling, braking, and even fuel consumption. Pure aluminum wheels can shave 10‑15% off the weight of a standard steel rim, while modern alloys can be another 5‑10% lighter than their aluminum‑only counterparts because the added metals allow engineers to thin out sections without sacrificing stiffness.

In real‑world terms, swapping a 17‑inch steel wheel (≈25kg) for a high‑quality alloy rim (≈15kg) can slash the rotating mass by 40%. That translates to quicker acceleration and less strain on the suspension. For most commuters, the fuel‑efficiency gain is modest-about 0.2L/100km-yet over a year of driving it adds up.

Strength and Durability

Alloy wheels get the durability badge because the alloy matrix distributes stress more evenly. The blend of metals creates a micro‑structure that resists cracking when you hit a pothole or take a hard curb. Aluminum, while light, is softer; it can dent more easily and may develop stress fractures over time, especially if you frequently load the vehicle.

Durability also ties to Strength is a measure of a material’s ability to withstand forces without permanent deformation. Tests from automotive labs in 2023 showed alloy wheels with a tensile strength of around 380MPa, versus pure aluminum wheels at roughly 310MPa. The difference means alloy rims can tolerate higher cornering loads without bending.

Cost Considerations

Historically, pure aluminum wheels were the budget option, while alloy wheels carried a premium. Today, advances in casting and extrusion have narrowed the gap. A set of 17‑inch alloy wheels for a midsize sedan typically ranges from $500 to $800 in Australia, while comparable aluminum wheels sit around $400 to $600. The extra cost buys you a sturdier wheel, better heat dissipation, and often a more polished finish.

If you’re on a tight budget, aluminum rims are still a viable choice, especially if you opt for a reputable brand that applies a protective coating.

Corrosion Resistance and Finishes

Both wheel types are prone to oxidation if left untreated, but the finishing process makes a huge difference. Powder‑coat finishes, clear‑coat urethane, and anodizing all add layers of protection. Anodized aluminum wheels, for example, create a hard oxide layer that can be up to 25µm thick, shielding the metal from road salt.

Alloy wheels often receive a double‑coat system: a base lacquer followed by a clear topcoat. This not only enhances shine but also blocks moisture. In coastal Brisbane, where sea spray can be aggressive, choosing a well‑coated alloy wheel can save you from premature rust.

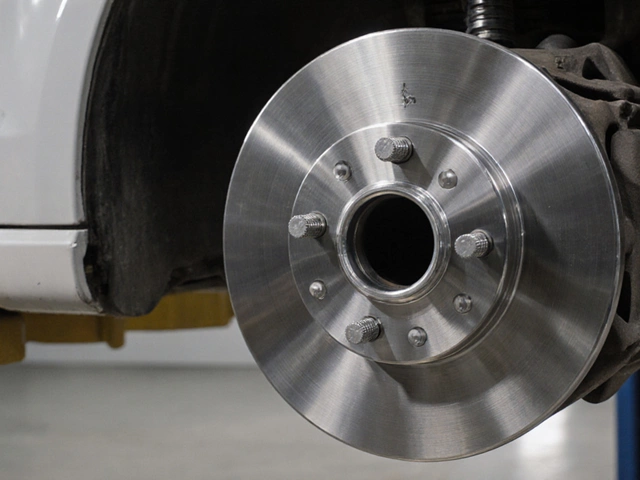

Brake Cooling and Heat Management

Heat buildup during hard braking can warp a wheel or degrade brake pads. Alloy wheels usually feature a more open design-think spoke patterns that let air flow-so they cool the brake rotors faster than dense aluminum wheels. The Brake cooling is a process of dissipating heat from the braking system via airflow through the wheel design advantage becomes evident on mountain roads or track days.

For city drivers who rarely push the brakes hard, the difference is negligible, but for enthusiasts, a well‑ventilated alloy rim can keep brake temperatures 15‑20°C lower in repeated hard stops.

Choosing the Right Wheel for Your Lifestyle

- Assess your driving style. If you enjoy spirited cornering, track days, or frequent highway passing, alloy wheels give you a stiffer, lighter platform.

- Consider the vehicle’s weight. Heavy SUVs benefit more from the added strength of alloy wheels, as the extra load can stress pure aluminum rims.

- Check local climate. In salty, coastal areas, prioritize a high‑quality coating or opt for anodized aluminum to combat corrosion.

- Budget reality. If you’re rebuilding a daily driver, pure aluminum wheels provide adequate performance at a lower price point.

- Match the aesthetic. Modern alloy designs often mimic forged looks without the price tag, giving your car a sportier appearance.

By answering these five checkpoints, you’ll land on the wheel that matches both your wallet and your road habits.

Side‑by‑Side Comparison

| Attribute | Aluminum Wheels | Alloy Wheels |

|---|---|---|

| Weight | Usually 2‑3kg lighter than steel | 5‑10% lighter than aluminum equivalents |

| Strength | ≈310MPa tensile strength | ≈380MPa tensile strength |

| Cost (AU$) | $400‑$600 per set | $500‑$800 per set |

| Corrosion Resistance | Depends on coating; anodizing common | Typically double‑coat paint or powder‑coat |

| Brake Cooling | Standard spoke designs; moderate airflow | Open‑spoke designs; superior airflow |

| Typical Use | Daily commuters, budget builds | Performance cars, enthusiast builds |

Maintenance Tips to Extend Wheel Life

Regardless of material, you’ll get the most out of your wheels by following a few simple habits:

- Wash the rims monthly with a pH‑balanced car shampoo to remove brake dust.

- Apply a dedicated wheel sealant after cleaning; it creates a hydrophobic layer that repels moisture.

- Inspect for curb‑impact dents after every long trip; small dents can propagate into cracks.

- Balance the wheels whenever you replace tires; unbalanced wheels increase stress on the spokes.

- Replace lug nuts with the correct torque (usually 80‑100Nm for passenger cars).

These steps keep both aluminum and alloy wheels looking sharp and performing reliably for years.

Frequently Asked Questions

Are alloy wheels really stronger than pure aluminum?

Yes. The blend of metals in an alloy creates a micro‑structure that can handle higher stresses without cracking, giving it a higher tensile strength compared to pure aluminum.

Do alloy wheels actually improve fuel economy?

The reduction in rotating mass can shave a few tenths of a litre per 100km, especially on city‑stop‑go traffic. On the highway the effect is smaller, but every little bit adds up over the year.

Can I repaint an alloy wheel with the same finish as a stock one?

Yes, but you need a professional powder‑coat or high‑temperature paint system. A DIY spray can look cheap and may not hold up against brake heat.

What size wheels are safe for a compact sedan?

Stick to the manufacturer’s recommended diameter and offset. For most compact sedans, 16‑ to 17‑inch wheels with a width of 6.5‑7.0inches work fine.

How often should I balance my wheels?

Every time you mount new tires, and at least once a year thereafter. Unbalanced wheels cause vibration and add stress to the spokes.